Refrigeration And Air conditioning systems

Moving heat from a lower temperature to higher temperature requires work to be done , according to second law of thermodynamics and this work can be done in many ways in different systems. The most widely used techniques to move heat from lower temperature to higher tempreatures are

1. Vapour Compression systems

2. Vapour absorption systems.

3. Peltier systems

4. Magnetic refrigeration systems

Vapour Compression systems are used onboard because of its high efficency and co-efficient of perfomance compared to vapour absorption systems. Vapour absorption cycles are not used now a days and has been phased out towards the beginning of 20th century.

Vapor Compression systems Explained:

Change of state is always associated with a latent heat of phase change and is absorbed from the surroundings. This is the principle behind vapour compression systems. The vapour used is cycled between liquid and gaseous phases. The liquid to gas phase change absorbs heat from the surrounding( the evaporator) and vapour to liquid change needs work to be done, and is supplied by a compressor.

Thus , in a vapour compression system, we must have a compressor which Compresses the refigerant vapor into high pressure vapour, a condesnor which cools the sub cooled liquid vapour into liquid phase, a TEV or thermostartic expansion valve or a capilliary tube, which regulates the flow of liquid and an evaporator in which the liquid refrigerant absorbs the heat and forms into saturated vapour. The vapour which comes out from the evaporator coils is not really saturated, but superheated , the reason of which is explained below.

The compressor:

Marine refrigeration sysetms widely use a multi cylinder electric motor driven reciprocating compressors. The advantage of such compressors is that the control of load can be employed using cutting in and cutting out of individual cylinders, which adds to be overall efficiency of the system.

The Air condition compressors crankcase is pressurized

The Air condition compressors crankcase is pressurized because of a bypass connection between compressor suction and the crankcase. This line is given because we cannot afford to lose even a small amount of refrigerant from the system. The piston- liner surface is not prefectlly sealed, even if high tech seal rings are used.There is always a little leakage from this interface, as in any other reciprocating systems.If the crankcase was vented to atmosphere, the refrigerant would escape into atmosphere. This gas which leaks from the interface is collected into the crank case of the compressor and is used back in the next cycle, by connecting crankcase and compressor suction side. Also oil carry over will be there in this arrangement which needs to be coped for.

In latest systems where oil ingress into the system is very much unacceptable, we use teflon or PTFE rings, which sweeps out the scope for piston lubrication. Such systems use a cross-head type piston, and isolates the liner and crankcase.

This is one of the major difference between Air condition compressor and Air compressors. Air compressor crankcase are open to atmosphere , as there is a breather given for the crank-case.

Varying the load on compressors:

The A/C compressor is having more than one unit when load control is required. The multi stage system is used so as to run the compressor at different loads. usually stages are set at 33%,66% and 100% loads. Each unit of compressors put in load according to the load on the system. A solenoid operating valve will keep the suction port depressed always when a unit is not in use. This removes the load on that particular unit. When the particular unit is needed to be on load, and add to the cooling capacity of the system the soleniod valve operates and removes the constraint placed earlier on the suction valve.

A compressor stages are usually setup to cut-in and cut-out based on the L.P or low pressure reading in the compressor suction side. This is explained well below in respective sections.

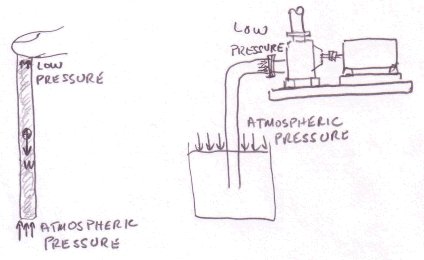

L.P and H.P sides of a compressor- The distinction -Why ??

The compression disharge line will be always pressurized compared to the suction side, and thus is called High Pressure side. Usually the line till the Thermostatic expansion valve is called H.P side. HP pressure refers to the pressure in this side, and is read by a guage fixed in the compressor discharge.

The compressor suction side from TEV to the suction port is at a Low Pressure, compared to the H.P side and this called L.P. evaporator pressure is always referred as L.P pressure, and is of very much importance in the refrigeration system.

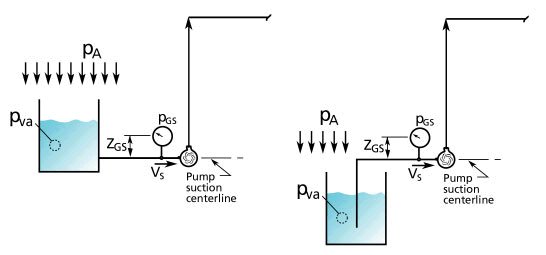

How Temperature of evaporator is controlled in refrigerators.- L.P CUTOUTS

The pressure in the evaporator is a measure of the evaporator temperature according to the gas laws. The vapor absorbs heat from the evaporator and its pressure rises at a constant temperature, as the phase change is taking place here without any super-heating. When the evaporator pressure or L.P falls to the pressure of the gas at that particular set temperature, the compressor cuts-out and system is at set-point. When the pressure in the evaporator increases, the compressor cuts in and starts the cycle.

Compressor stages are set at to cut-in at diffeerent L.P pressures. If a particular temperature cannot be achieved by a particular no of stages, the L.P pressure increases and at the cutting in point the next stage cuts in.

Vegetable room at 4 Degrees and Meat room at -18??? Same compressor??? :O

This is achieved by using back pressure valves in the individual lines from each of these spaces. L.P in each of the evaporator is controlled by this back pressure valve, and thus controls the temperature.Each of the back-pressure valve maintains a particular pressure inside the system, and thus ensures a particular temperature in the system. So, L.P of vegetable room will have a higher valuse than L.P of meat room. Each of the evaporator is having its own expansion valves.

Thermo static Expansion valves

These are flow control devices used in refrigeration systems.The degree of superheat of vapour after the evaporator to the compressor suction side is maintained by the There is an orifice as the main part of the valve, which will open and close based upon demand of the evaporator. This is NOT the device which maintains pressure gradient in the system , and it is the compressor which is doing so.

How does TEV control degree of superheat?? Why vapour is superheated ???

A saturated vapour is always appreciated inside the evaporator coils as heat transfer is most efficient during phase change. When superheating happens, lesser amount of energy is absorbed and thus is inefficient. Even though superheating is unfavourable, we always keep a small degree of supreheat for the vapour coming into the compressor suction side. This is done in order to avoid entry of any liquid into the compressor, as it may badly affect it.

TEV's sensing bulb is placed near to the compressor suction where vapour is present in the supreheated form inside the L.P tube. The vapour inside evaporator is now superheated and the feeler bulb has saturated vapour inside it. Saturated vapour pressure is always greater than superheted vapour pressure at the same temperature. This pressure difference is directly related to the degree of superheat. Thus TEV operates on this pressure difference as input, and not the pressure inside the feeler bulb as input. When degree of superheat falls below a value, this pressure gradiant lowers, and TEV remains closed for a longer period, lowering flow of refrigerant liquid into evaporator coils, and pulls up the degree of superheat.

In large installations an equlizing line is given to balance the feeler bulb pressure in the TEV. This is in order to compensate for the pressure loss in evaporator coils due to friction of the coils. This pressure loss will create an increase in degree of superheat making the liquid refrigerant vapourizing completely before the end of evaporator coils. The effect is nullified by using a equalizer line.

TEV's sensing bulb is placed near to the compressor suction where vapour is present in the supreheated form inside the L.P tube. The vapour inside evaporator is now superheated and the feeler bulb has saturated vapour inside it. Saturated vapour pressure is always greater than superheted vapour pressure at the same temperature. This pressure difference is directly related to the degree of superheat. Thus TEV operates on this pressure difference as input, and not the pressure inside the feeler bulb as input. When degree of superheat falls below a value, this pressure gradiant lowers, and TEV remains closed for a longer period, lowering flow of refrigerant liquid into evaporator coils, and pulls up the degree of superheat.

In large installations an equlizing line is given to balance the feeler bulb pressure in the TEV. This is in order to compensate for the pressure loss in evaporator coils due to friction of the coils. This pressure loss will create an increase in degree of superheat making the liquid refrigerant vapourizing completely before the end of evaporator coils. The effect is nullified by using a equalizer line.

.PNG)

[1]

[1] where

where [2]

[2]